Product Center

YunfuDisc washer

Category:

YunfuDisc washer

Product description

| Specifications | Description | Tolerance Range |

| Nominal Outer Diameter (D) | Maximum diameter of the gasket outer edge, suitable for installation space | Small size (D≤10mm): ±0.05mm; Medium size (10mm<D≤50mm): ±0.1mm; Large size (D>50mm): ±0.2mm |

| Inner Hole Diameter (d) | Hole diameter or clearance structure for shafts and rods | Small size (d≤5mm): ±0.03mm; Medium size (5mm<d≤30mm): ±0.05mm; Large size (d>30mm): ±0.1mm |

| Nominal Thickness (t) | Static thickness under no pressure, related to elastic reserve | Ultra-thin type (t≤0.5mm): ±0.02mm; Conventional type (0.5mm<t≤3mm): ±0.05mm; Thick type (t>3mm): ±0.1mm |

| Butterfly Arch Height (h) | Arch height under no pressure, determining deformation stroke | Small arch height (h≤1mm): ±0.05mm; Conventional arch height (1mm<h≤5mm): ±0.1mm; Large arch height (h>5mm): ±0.2mm |

| Planarity | Flatness of the gasket pressure surface | Small size (D≤20mm): ≤0.03mm; Medium size (20mm<D≤60mm): ≤0.05mm; Large size (D>60mm): ≤0.1mm |

| Concentricity | Offset of the center of the inner hole and the outer diameter | Small size: ≤0.05mm; Medium and large sizes: ≤0.1mm; Custom high precision: ≤0.02mm (such as optical equipment matching) |

| Surface Roughness (Ra) | Degree of microscopic undulation of the surface | Medical grade (implantation, etc.): Ra≤0.4μm; Industrial sealing grade: Ra≤0.8μm; Conventional grade: Ra≤1.6μm |

Product Use/Application Scenarios

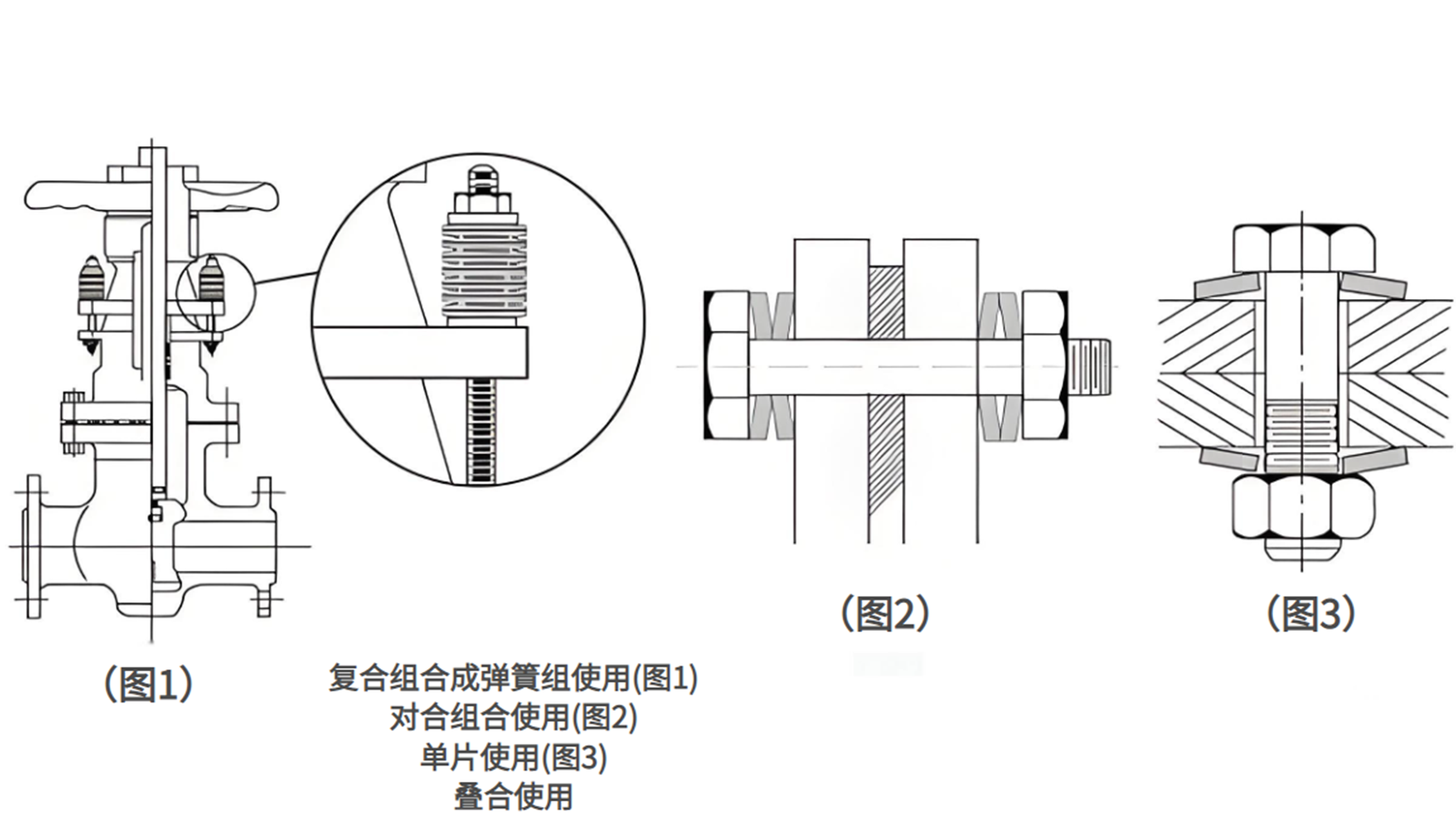

Nickel butterfly gaskets are widely used in the industrial sectors of machinery manufacturing, energy and power, petrochemicals, and electronic communications. In machinery manufacturing, they are used for precision equipment shock absorption and bolt loosening prevention; in the energy and power field, they are suitable for new energy battery module connection and high-voltage equipment sealing; in the petrochemical industry, they are capable of sealing high-temperature and high-pressure pipelines; and in the electronic communications industry, they are used for flexible circuit clamping and sensor component support.