Product Center

Bao'anShape memory alloy spring

Category:

Bao'anSpring

Product description

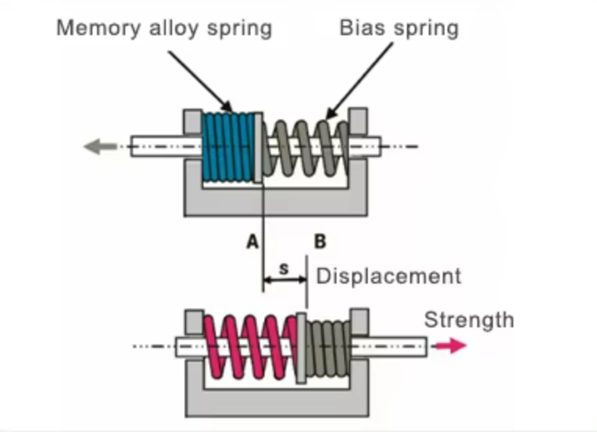

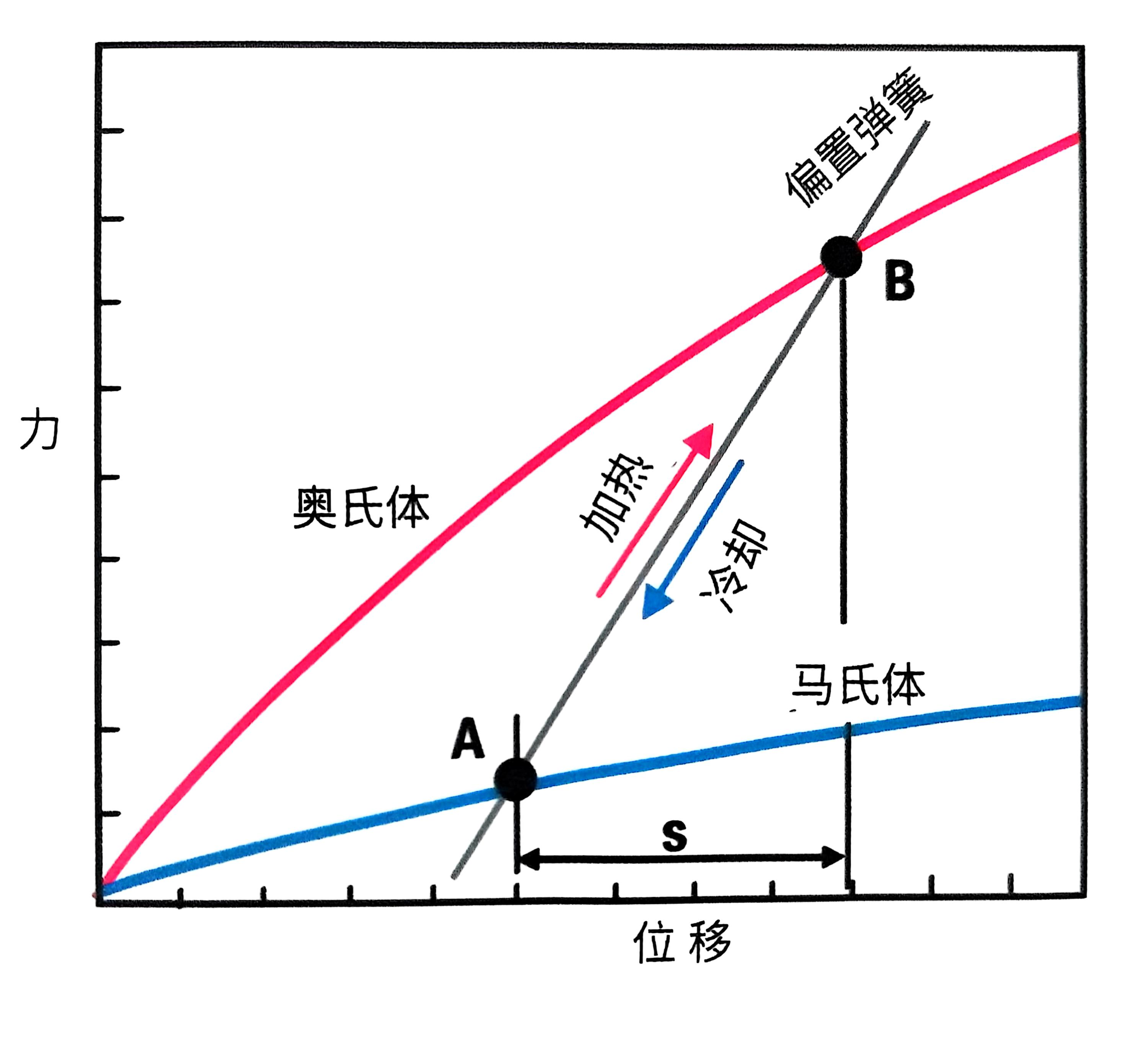

Mechanical and Functional Characteristics of Several Compression Springs

| Mean Diameter | Free Length (L0) | Wire Diameter | Estimated Force Value | Stroke |

| 14 | 130 | 1,5 | 20 | 30 |

| 10 | 25 | 1,5 | 14 | 8 |

| 9 | 16 | 2,2 | 50 | 2 |

| 6 | 18 | 1,5 | 30 | 3 |

| 3 | 8 | 0,6 | 2 | 2 |

Shape memory alloy compression springs can be customized according to your design and application requirements.

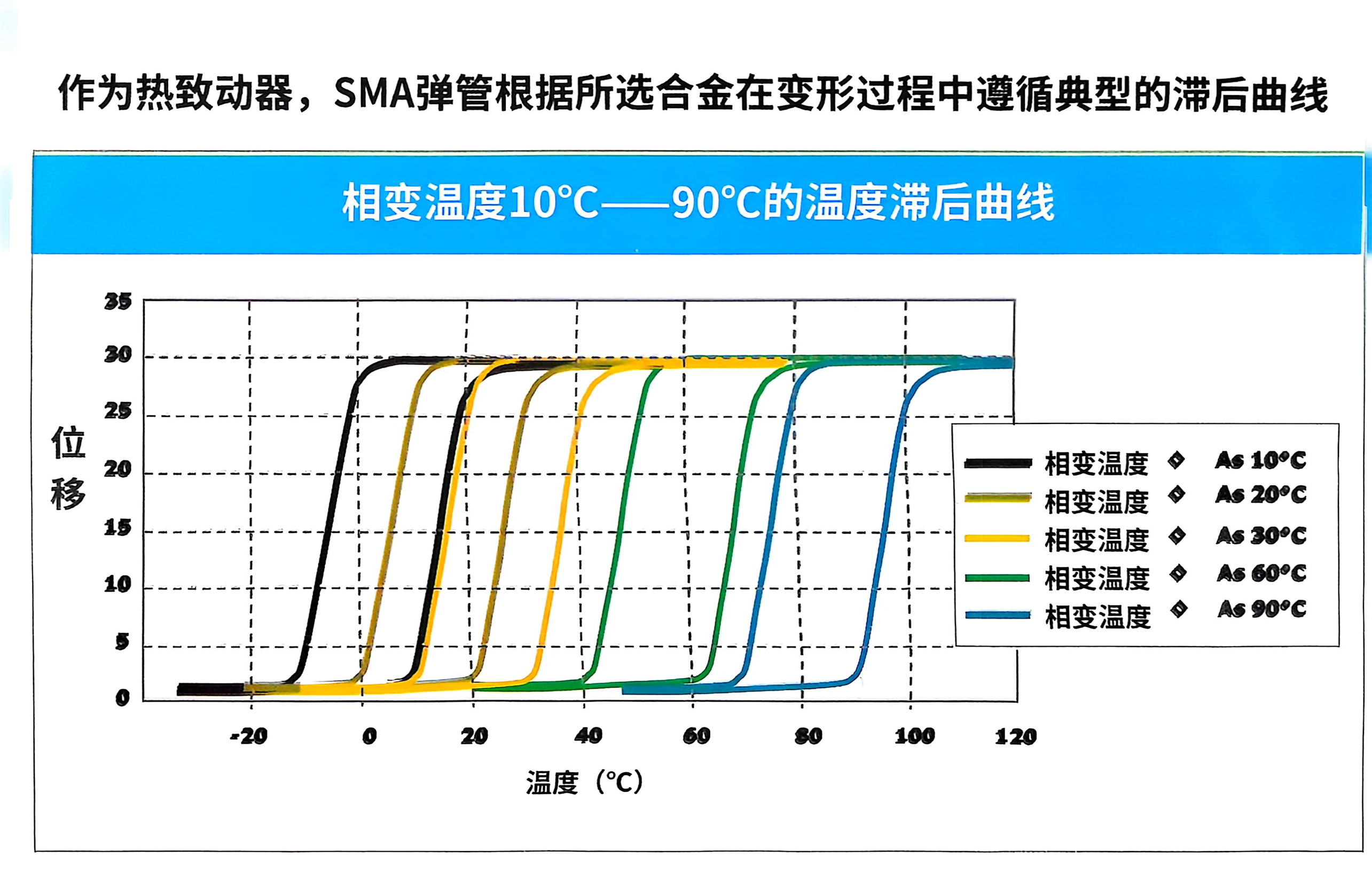

Product Use/Application Scenarios

Bathroom equipment: Temperature control spring adjusts water temperature to prevent scalding. Temperature control valve core

Smart devices: Used as sensor components in temperature-triggered automatic control scenarios.

Aerospace components: Stable operation under extreme temperatures, compensating for thermal stress. Aircraft structural components, aero engines, miniature electronic components, oil circuit cooling

Next

Hotline:

Contact Email:

Address:

Building 19, Liandong U Valley, Sanhe Subdistrict, Huiyang District, Huizhou City, Guangdong Province, China

NiTinol -Titanium Memory Alloy Wire | NiTinol Spring | NiTinol - Fastening Ring

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Follow WeChat

Add WeChat

Power by:www.300.cn | Tag | Privacy Policy | City List