2025/04/17

Future Prospects of Shape Memory Alloy High-Tech Applications

The 20th century was the era of mechatronics. Sensing-integrated circuits-driving is the most typical mechatronics control system, but it is complex and large. Shape memory materials have both sensing and driving functions, which can achieve miniaturization and intelligence of the control system, such as holographic robots and millimeter-level ultra-miniature manipulators. The 21st century will be the era of materials electronics. The movements of shape memory alloy robots are not affected by any environmental conditions except temperature, and are expected to play a major role in high-tech fields such as reactors, accelerators, and space laboratories.

2025/04/16

Application of shape memory alloys in aerospace industry

Shape memory alloys (SMAs) are widely used in various fields such as aerospace, mechatronics, biomedicine, bridge construction, automotive industry, and daily life due to their many excellent properties. SMAs have been applied to aerospace devices. For example, they are used in low-temperature coupling connectors in the hydraulic systems of military aircraft. Europe and the United States are developing SMA materials for intelligent horizontal rotors in helicopters. Due to the limitations of high vibration and noise in helicopter use, the sources of noise and vibration are mainly blade vortex interference and minor deviations in blade profiles. This requires a device to balance the blade pitch so that each blade can rotate precisely in the same plane. A blade trajectory controller has been developed, which uses a small, double-tube SMA actuator to control the position of small flaps on the blade edge trajectory, minimizing vibration. They can also be used to manufacture lunar antennas for exploring the mysteries of the universe. People use SMAs to make antennas in high-temperature environments, then compress them into a small iron ball at low temperatures, reducing their volume to one-thousandth of the original. This makes it easy to transport to the moon. The strong radiation of the sun restores it to its original shape, sending valuable cosmic information back to Earth as needed. In addition, a shape memory release device is used in satellites to open a container that protects sensitive germanium detectors from contamination during assembly and launch.

2025/04/16

Applications of shape memory alloys in mechatronics and biomedical fields

Mechanical and Electronic Products In 1970, the United States used shape memory alloys to produce cryogenic coupling connectors for the F-14 fighter, followed by millions of applications. Shape memory alloys are used as cryogenic coupling connectors in aircraft hydraulic systems and smaller petroleum, petrochemical, and electrical industrial products. Another type of connector is a welded mesh of metal wires, used to make safety joints for the metal wire braided layers of conductors. This type of connector has been used in sealing devices, electrical connection devices, and electronic engineering machinery, and can reliably operate at -65~300℃. A developed sealing system device can be used as an electrical component connection in harsh environments. Shape memory alloys are made into a spring that can open and close a shutter to protect fog lights from damage by flying debris. Used in the manufacture of precision instruments or precision lathes, if deformation occurs due to vibration, collision, etc., the fault can be eliminated simply by heating. In the mechanical manufacturing process, various stamping and mechanical operations often require transferring parts from one machine to another. Now, a device called a drive cylinder, which uses shape memory alloys, has been developed to replace manual or hydraulic fixtures. This device is characterized by high efficiency, flexibility, and large clamping force. Biomedical TiNi shape memory alloys used in the medical field must meet chemical and biological requirements, i.e., good biocompatibility, in addition to utilizing their shape memory effect or superelasticity. TiNi can form a stable passivation film with the organism. In medicine, TiNi alloys are mainly used in: (a) Orthodontic wires: Orthodontic wires made of superelastic TiNi alloy wires and stainless steel wires, among which superelastic TiNi alloy wires are the most suitable. Usually, orthodontic wires use stainless steel wires and CoCr alloy wires, but these materials have the disadvantages of high elastic modulus and small elastic strain. In order to provide a suitable correction force, they must be processed into an arc shape before correction, and ligation and fixation require skilled techniques. If TiNi alloy is used as an orthodontic wire, even if the strain is as high as 10%, no plastic deformation will occur, and the stress-induced martensite phase transformation makes the elastic modulus exhibit non-linear characteristics, i.e., the correction force fluctuates very little as the strain increases. This material is not only easy to operate and has good therapeutic effect, but also can reduce patient discomfort. (b) Spinal scoliosis correction: Various spinal scoliosis diseases (congenital, habitual, neurological, rachitic, idiopathic, etc.) not only cause serious damage to the body and mind, but also compress the internal organs, so surgical correction is necessary. Currently, this surgery uses stainless steel Harrington rods for correction. During the placement of the correction rods, it is required that the correction force on the fixed spine be kept below 30~40kg. If the force is too large, the correction rod will be damaged, resulting in damage not only to the spine but also to the nerves. At the same time, the correction force after the placement of the correction rod will change with time. When the correction force drops to about 30% of the initial value, another surgery is needed to adjust the correction force, which causes great pain to the patient both mentally and physically. With Harrington rods made of shape memory alloy, only one placement and fixation of the correction rod is needed. If the correction force of the correction rod changes, the shape memory alloy can be heated externally to raise the temperature by about 5℃ above body temperature to restore sufficient correction force. In addition, TiNi shape memory alloys are used in surgery to make various bone connectors, vascular clips, blood clot filters, and vascular expansion components. They are also widely used in stomatology, orthopedics, cardiovascular surgery, thoracic surgery, hepatobiliary surgery, urology, gynecology, etc. With the development of shape memory alloys, medical applications will become even more extensive.

2025/04/08

Shape memory alloy: What are the unique properties of shape memory alloys?

Shape memory alloys are a new type of functional material that undergoes phase transformation under the action of temperature and stress. It has unique characteristics such as shape memory effect and pseudoelasticity. Shape memory alloys are widely used in aerospace, medical devices, and mechanical and electrical equipment. So, what are the unique properties of shape memory alloys? Let's take a look!

2025/04/07

Applications of shape memory alloys in building structures and daily life

Building Structures Utilizing the pseudo-elasticity and dynamic damping characteristics of shape memory alloys (SMAs), SMAs are used in passive control structures affected by earthquakes, playing an anti-seismic role. They are also applied in active damping control of structural vibrations. Daily Life (a) Anti-scalding Valves: In home life, developed shape memory valves can prevent accidental scalding from hot water in washing sinks, bathtubs, and bathrooms; these valves can also be used in hotels and other suitable places. If the water temperature from the tap reaches a temperature that could scald (approximately 48℃), the shape memory alloy drives the valve to close until the water temperature drops to a safe temperature, at which point the valve reopens. (b) Eyeglass Frames: Assembling TiNi alloy in the bridge and temples of eyeglass frames provides comfort and wear resistance. The flexibility of TiNi alloys has made them widely used in changing eyeglass fashion. Using superelastic TiNi alloy wire for eyeglass frames ensures that even with lens thermal expansion, the shape memory alloy wire can firmly clamp the lens with a constant force due to its superelasticity. These superelastic alloy eyeglass frames have a much greater deformation capacity than ordinary frames. (c) Mobile Phone Antennas and Fire Check Valves: Using superelastic TiNi metal wire for honeycomb-shaped phone antennas is another application of shape memory alloys. Previously, stainless steel antennas were used, but damage often occurred due to bending. Mobile phone antennas made with TiNi shape memory alloy wire have high damage resistance and are widely popular. Therefore, they are often used to make honeycomb-shaped phone antennas and fire check valves. In a fire, when a local area heats up, the valve automatically closes, preventing dangerous gases from entering. The advantage of this specially designed structure is that it allows for the operation of the check valve and then resets to a safe state; this type of fire check valve is used in the semiconductor manufacturing industry, where toxic gases are used in the diffusion process of semiconductor manufacturing; this fire check valve can also be applied in chemical and petroleum plants. Other Applications The potential of using TiNi shape memory alloys as sound insulation materials and for detecting and controlling earthquake damage in engineering and construction has been demonstrated. Applications in bridges and buildings have been tested, making their use as sound insulation materials and for damage control a new application area. With the emergence and development of thin-film shape memory alloy materials, shape memory alloys are receiving significant attention in intelligent material systems, with even broader application prospects.

2025/04/06

NiTinol-titanium memory alloy flat wire_memory alloy wire_NiTinol-titanium memory alloy plate

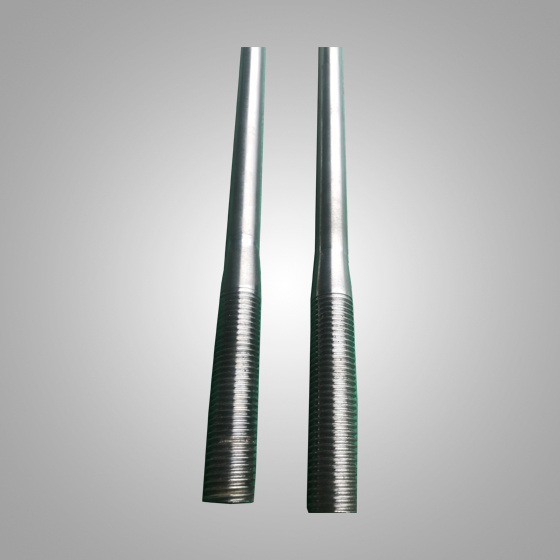

NiTinol-titanium memory alloy flat wire_Memory alloy wire_NiTinol-titanium memory alloy plate Shaanxi Pengda Memory Materials Technology Co., Ltd., located in Baoji, Shaanxi, a well-known non-ferrous metal production and research base in China, is a modern high-tech enterprise specializing in the research, development, production, sales, and service of NiTinol-titanium memory alloy materials, as well as titanium-based, NiTinol-based, niobium-based, and zirconium-based memory alloy materials. The company's main products include NiTinol-titanium memory alloy wires, wires, flat wires, rods, plates, tubes, and special-shaped materials and products, serving the aerospace, chemical, electronic, medical, and civilian industries. Main products include NiTinol-titanium memory alloy flat wire, memory alloy wire, NiTinol-titanium memory alloy plate, NiTinol-titanium memory alloy wire, memory alloy flat wire, memory alloy plate, and NiTinol-titanium memory alloy. Since its establishment, the company has leveraged the advantages of its R&D team and collaborated with the Northwest Institute of Non-ferrous Metals to continuously develop new materials and processes. It has built several high-end memory alloy wire production lines, and its products are exported to countries and regions including Europe, America, Japan, South Korea, and Singapore, receiving consistent recognition from customers at home and abroad. The company is committed to technological innovation and quality improvement, utilizing years of experience in materials processing and management to build a leading brand of high-quality NiTinol-titanium memory alloys and provide customers with high-quality products and services.

2025/04/06

NiTinol-titanium memory alloy wire_memory alloy flat wire_memory alloy sheet

NiTinol-titanium memory alloy wire_Memory alloy flat wire_Memory alloy plate Shaanxi Pengda Memory Materials Technology Co., Ltd., located in Baoji, Shaanxi, a well-known non-ferrous metal production and research base in China, is a modern high-tech enterprise specializing in the research, development, production, sales, and service of NiTinol-titanium memory alloy materials, as well as titanium-based, NiTinol-based, niobium-based, and zirconium-based memory alloy materials. The company's main products include NiTinol-titanium memory alloy wires, wires, flat wires, rods, plates, tubes, and special-shaped materials and products, serving the aerospace, chemical, electronic, medical, and civilian industries. Main products include NiTinol-titanium memory alloy flat wire, memory alloy wire, NiTinol-titanium memory alloy plate, NiTinol-titanium memory alloy wire, memory alloy flat wire, memory alloy plate, and NiTinol-titanium memory alloy. Since its establishment, the company has leveraged the advantages of its R&D team and collaborated with the Northwest Institute of Non-ferrous Metals to continuously develop new materials and processes. It has built several high-end memory alloy wire production lines, and its products are exported to countries and regions including Europe, America, Japan, South Korea, and Singapore, and have been widely recognized by customers at home and abroad. The company is committed to technological innovation and quality improvement, and uses years of experience in materials processing and management to build a leading brand of high-quality NiTinol-titanium memory alloys, providing high-quality products and services to customers.

2025/04/06

Below is an explanation of the principles of shape memory alloys and their industrial applications

Below is an explanation of the principle of shape memory alloys and their industrial applications. Shape memory alloys are martensitic transformation alloys with ordered atomic arrangements and a volume less than 0.5%. These alloys deform under external force and, upon removal of the force, recover their original shape at a certain temperature. They are called "shape memory alloys" because they can recover their shape over one million times. Next, the author introduces the principle and classification of shape memory alloys.

2025/04/05

NiTinol-titanium memory alloy_Memory alloy wire_Memory alloy flat wire

NiTinol-titanium memory alloy_Memory alloy wire_Memory alloy flat wire Shaanxi Pengda Memory Materials Technology Co., Ltd., located in Baoji, Shaanxi, a well-known non-ferrous metal production and research base in China, is a modern high-tech enterprise specializing in the research, development, production, sales, and service of NiTinol-titanium memory alloy materials, as well as titanium-based, NiTinol-based, niobium-based, and zirconium-based memory alloy materials. The company's main products include NiTinol-titanium memory alloy wires, wires, flat wires, rods, plates, tubes, and special-shaped materials and products, serving the aerospace, chemical, electronic, medical, and civilian industries. Main products include NiTinol-titanium memory alloy flat wire, memory alloy wire, NiTinol-titanium memory alloy plate, NiTinol-titanium memory alloy wire, memory alloy flat wire, memory alloy plate, and NiTinol-titanium memory alloy. Since its establishment, the company has leveraged the advantages of its R&D team and collaborated with the Northwest Institute of Non-ferrous Metals to continuously develop new materials and processes. It has built several high-end memory alloy wire production lines, and its products are exported to Europe, America, Japan, South Korea, Singapore and other countries and regions, and have been widely recognized by customers at home and abroad. The company is committed to technological innovation and quality improvement, and uses years of material processing and management experience to build a leading brand of high-quality NiTinol-titanium memory alloys, providing high-quality products and services to customers.

2025/04/04

NiTinol-titanium memory alloy plate_NiTinol-titanium memory alloy wire_NiTinol-titanium memory alloy

NiTinol-titanium memory alloy sheet_NiTinol-titanium memory alloy wire_NiTinol-titanium memory alloy Shaanxi Pengda Memory Materials Technology Co., Ltd., located in Baoji, Shaanxi, a well-known non-ferrous metal production and research base in China, is a modern high-tech enterprise specializing in the research, development, production, sales, and service of NiTinol-titanium memory alloy materials, as well as titanium-based, NiTinol-based, niobium-based, and zirconium-based memory alloy materials. The company's main products include NiTinol-titanium memory alloy wires, wires, flat wires, rods, plates, tubes, and special-shaped materials and products, serving the aerospace, chemical, electronic, medical, and civilian industries. Main products include NiTinol-titanium memory alloy flat wire, memory alloy wire, NiTinol-titanium memory alloy plate, NiTinol-titanium memory alloy wire, memory alloy flat wire, memory alloy plate, and NiTinol-titanium memory alloy. Since its establishment, the company has leveraged the advantages of its R&D team and collaborated with the Northwest Institute of Non-ferrous Metals to continuously develop new materials and processes. It has built several high-end memory alloy wire production lines, and its products are exported to countries and regions such as Europe, America, Japan, South Korea, and Singapore, and have been widely recognized by customers at home and abroad. The company is committed to technological innovation and quality improvement, and uses years of material processing and management experience to build a leading brand of high-quality NiTinol-titanium memory alloys, providing high-quality products and services to customers.