PRODUCT CATEGORY

Product Center · Customizable

Mainly engaged in:In-depth research on the process and performance of memory alloys, independent innovation, and excellent processes for NITI shape memory alloy superelasticity processing, single-way memory processing, two-way memory processing, and full-process memory processing.

Huizhou Zhilian Smart Nitinol Co., Ltd

A professional manufacturer in the field of memory alloy processing!

Memory Alloy: Development | Production | Technical Service

Huizhou Zhilian Smart Nitinol Co., Ltd has many experts in the field of memory alloys. Based on the rapidly developing Pearl River Delta, relying on years of in-depth research on the process and performance of memory alloys, independent innovation, and excellent processes for NITI shape memory alloy superelasticity processing, single-way memory processing, two-way memory processing, and full-process memory processing. The products produced are widely used in automobiles, high-speed rail, electric power, aerospace, medical devices and other fields. In many fields, it has helped customers optimize product structure and enhance product competitiveness...

Huizhou Zhilian Smart Nitinol Co., Ltd is a professional manufacturer in the field of memory alloy processing in China.

The company was founded in 2019

Registered capital of 5 million yuan

Number of employees

Honorary Qualifications

Floor area

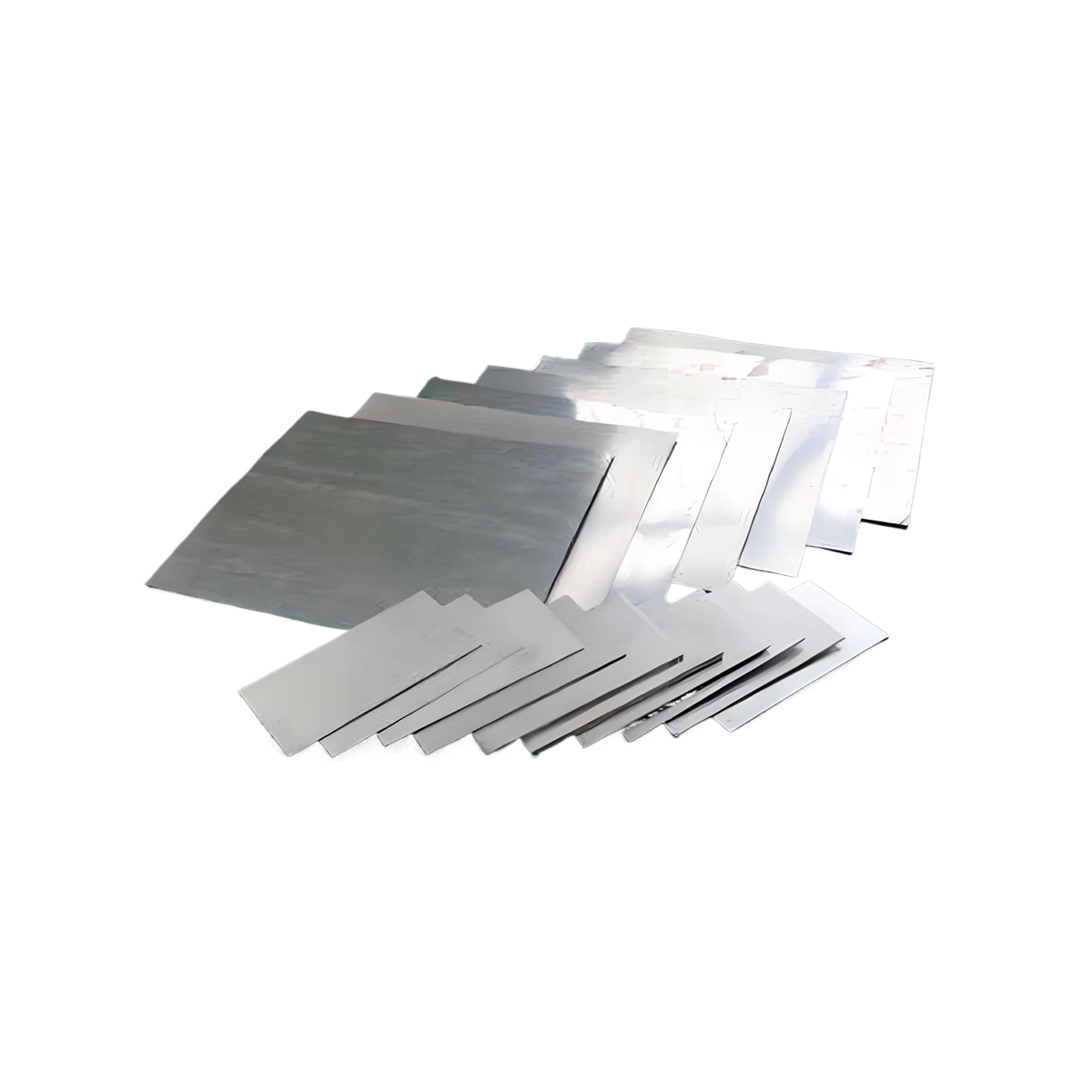

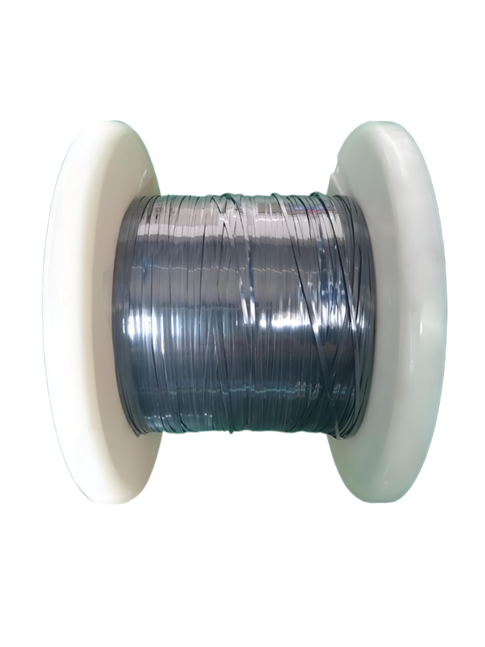

Popular Products

Relying on years of in-depth research on the process and performance of memory alloys, independent innovation, and excellent processes for NITI shape memory alloy superelasticity processing, single-way memory processing, two-way memory processing, and full-process memory processing.

CORE COMPETENCIES

Pay attention to every detail with heart

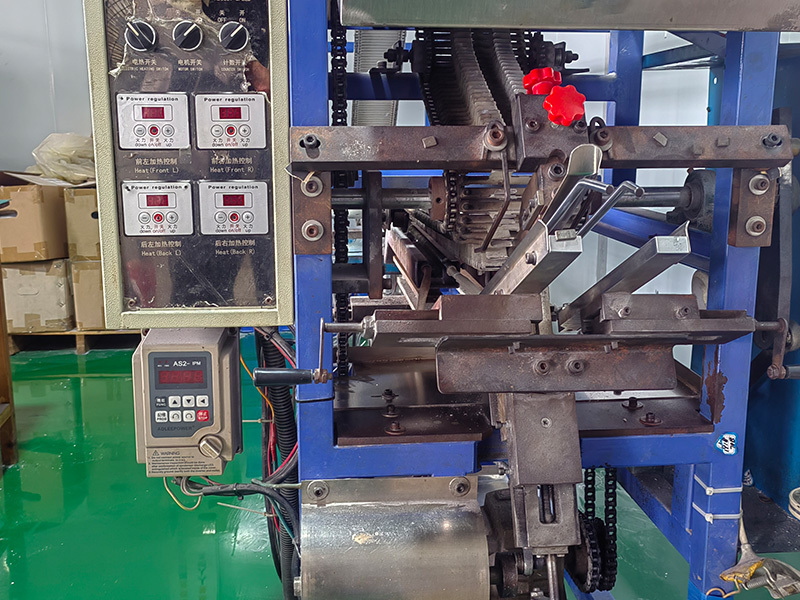

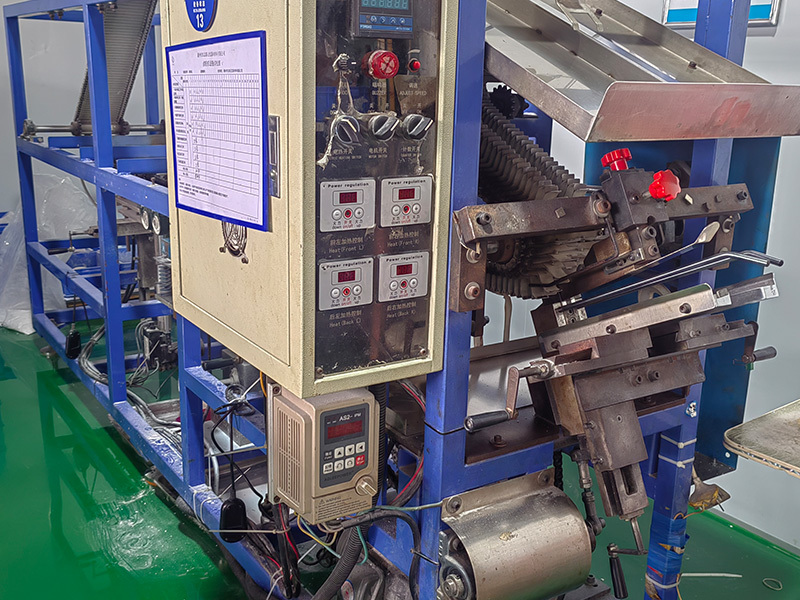

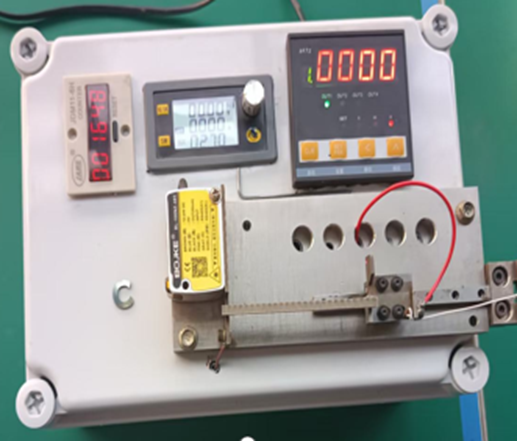

Main Equipment

Technical and quality control personnel

Various management personnel

Surface treatment

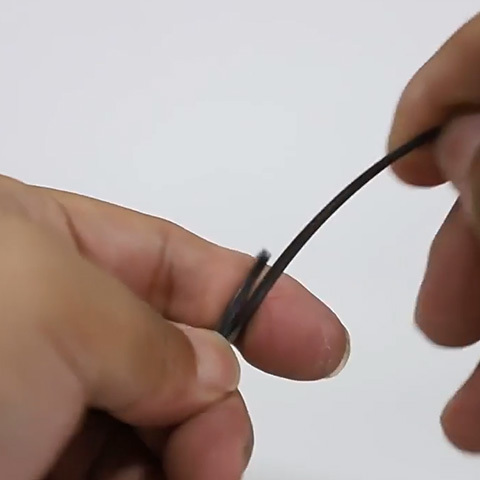

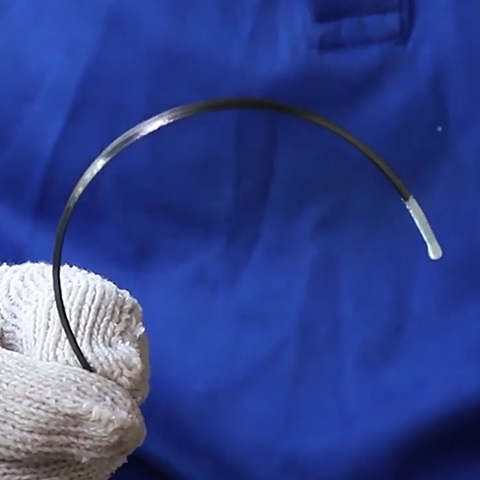

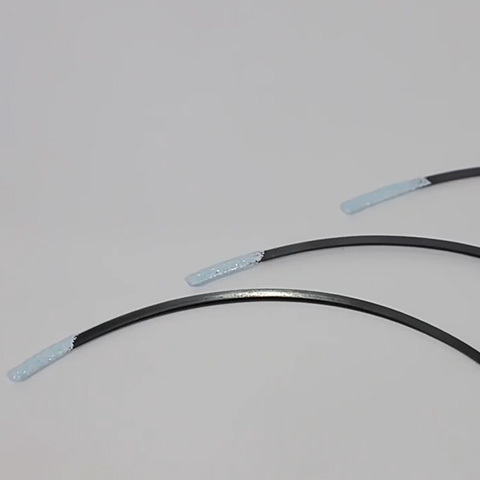

Smooth surface without burrs, stable performance, and wide range of applications

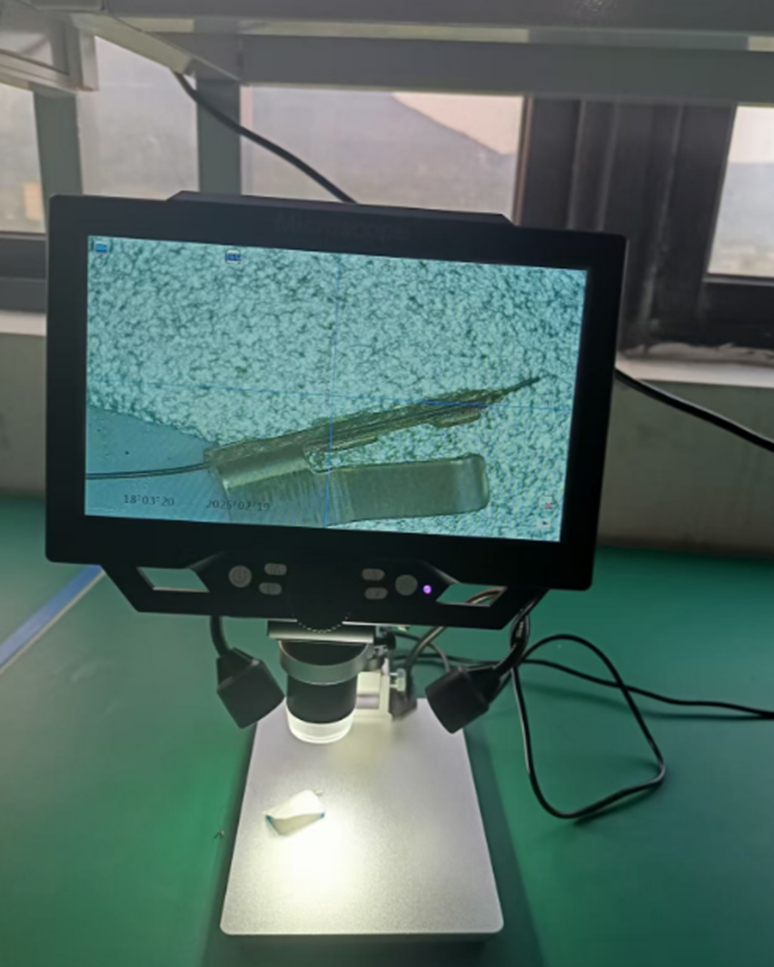

Strict quality control

Use instruments and equipment to conduct strict tests on products, through multiple processes, to ensure that products meet standards.

Quality without worry

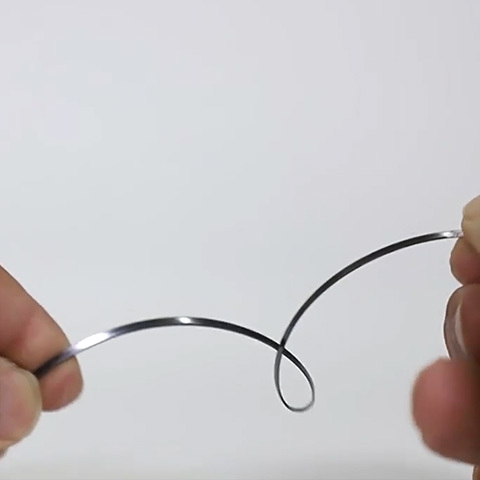

Strong toughness, not easy to deform under strong pressure, good rebound

Customization

Years of experience in OEM industry from the source factory, quality is more guaranteed

APPLICATION

Application areas

The products produced are widely used in automobiles, high-speed rail, electric power, aerospace, medical devices and other fields. It has helped customers in many fields optimize product structure and enhance product competitiveness.

NEWS CENTER

News

Gather the latest news in the field of shape memory alloy processing